What is the Future of Carbon Fiber?

Carbon fiber has been around for more than half a century and has already made a significant impact in various industries. It is a strong, lightweight material that is popularly used in the aerospace, automotive, and sports equipment industries. As technology continues to advance, what does the future hold for carbon fiber? Will it continue to dominate as a material of choice, or will it be replaced by new materials that offer better properties? In this article, we will explore the future of carbon fiber and its potential impact on different industries.

The Current State of Carbon Fiber

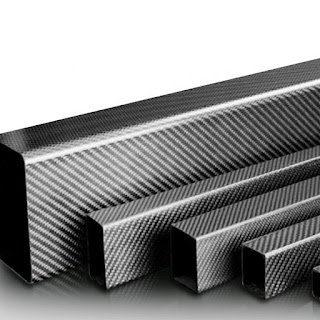

Carbon fiber is made

by weaving

or knitting carbon filaments into a fabric, which is then impregnated with a

resin and cured in an oven to create a rigid structure. The resulting material

has a high strength-to-weight ratio, making it ideal for applications where

weight reduction is critical. Carbon fiber is commonly used in the aerospace

industry for aircraft parts, such as wings and fuselages, and in the automotive

industry for components like body panels and suspension parts.

One of the primary

benefits of carbon fiber is its strength, stiffness, and durability. It can

withstand high temperatures and is resistant to corrosion, making it an

excellent choice for use in harsh environments. Carbon fiber is also

electrically conductive, making it useful in electronic and electrical

applications. The material's unique properties have also led to its use in

other industries such as wind energy, sporting goods, and medical

devices.

The Future of Carbon Fiber

The future of carbon

fiber looks bright as advancements in technology continue to improve its

performance and reduce its production costs. Here are some of the potential

developments that could shape the future of carbon fiber:

- Improved

Manufacturing Processes

Currently, the

manufacturing process for carbon fiber involves weaving and curing individual

strands of carbon filaments. This process is time-consuming and expensive,

limiting the use of carbon fiber in mass-produced applications. However, new

manufacturing techniques such as 3D printing and automated fiber placement

could make carbon fiber production faster, cheaper, and more accessible.

- Recycling

Carbon Fiber

As the use of carbon

fiber continues to grow, so does the amount of waste generated during

production and disposal. Recycling carbon fiber could help reduce waste and

lower production costs. Researchers are currently exploring methods to recycle

carbon fiber, such as pyrolysis and solvolysis, to recover the material's valuable

properties.

- Integration

with Other Materials

Carbon fiber can be

combined with other materials to create composites that offer unique

properties. For example, carbon fiber can be integrated with metals to create

lightweight, high-strength materials that are ideal for aerospace and

automotive applications. Combining carbon fiber with plastics could also create

materials that are durable and lightweight.

- Nanotechnology

Nanotechnology could

revolutionize the way carbon fiber is produced and used. Researchers are

exploring the use of carbon nanotubes, which are stronger and lighter than

traditional carbon fiber, in composite materials. Carbon nanotubes could also

be used to create electrical conductors, energy storage devices, and biomedical

implants.

Impact on Different Industries

The potential

advancements in carbon fiber could have a significant impact on different

industries:

- Aerospace

Industry

The aerospace industry is

one of the largest consumers of carbon fiber, and any advancements in

manufacturing and recycling could significantly reduce production costs.

Improvements in carbon fiber properties could also lead to the development of

new aircraft designs that are more fuel-efficient and environmentally friendly.

- Automotive

Industry

The automotive industry

is also a major user of carbon fiber, with applications ranging from body

panels to suspension parts. The integration of carbon fiber with other

materials could lead to the development of lighter, stronger, and more

fuel-efficient vehicles.

- Sports

Equipment Industry

Carbon fiber is widely

used in the sports equipment industry, with applications ranging from bicycle

frames to tennis rackets and golf clubs. Improvements in carbon fiber

technology could lead to the development of more durable, lightweight, and

high-performance sports equipment.

- Wind

Energy Industry

Carbon fiber is used

in the construction of wind turbine blades, which must be lightweight and

durable to withstand harsh weather conditions. The use of carbon fiber in wind

energy could increase as production costs decrease and recycling methods

improve.

Challenges and Limitations

Despite the potential

benefits of carbon fiber, there are still some challenges and limitations that

must be addressed:

- Cost

Carbon fiber

production is still expensive, which limits its use in mass-produced

applications. Improving manufacturing processes and recycling methods could

help lower production costs and increase accessibility.

- Sustainability

The production and

disposal of carbon fiber generate significant waste and environmental impacts.

Recycling carbon fiber could help reduce waste, but sustainable production

methods and disposal solutions are also needed.

- Material

Properties

While carbon fiber has

excellent properties, it is not suitable for all applications. For example, it

is not as impact-resistant as some metals and plastics, which limits its use in

some industries.

Conclusion

The future of carbon

fiber looks promising as advancements in technology continue to improve its

properties and reduce production costs. New manufacturing

processes, recycling methods, and nanotechnology could revolutionize

the way carbon fiber is produced and used. The impact of these advancements

could be significant in industries such as aerospace, automotive, sports equipment,

and wind energy. However, challenges such as cost, sustainability, and material

properties must be addressed to realize the full potential of carbon fiber.

Overall, carbon fiber will continue to be an important material in various

industries, and its future looks bright.